Visitors to our workshop are often intrigued about the origin of the wood that is used to make the Bradbury Cricket bats. The clefts of cricket bat willow are stacked in the workshop before the crafting begins. However, there is a great deal of work that has already taken place to get them from England to Australia.

Visitors to our workshop are often intrigued about the origin of the wood that is used to make the Bradbury Cricket bats. The clefts of cricket bat willow are stacked in the workshop before the crafting begins. However, there is a great deal of work that has already taken place to get them from England to Australia.

Australia is known for having strict quarantine requirements for entry of wood products. The willow is required to be treated and certified before being cleared for delivery. Interestingly, completed cricket bats entering the country do not require the same stringent red tape.

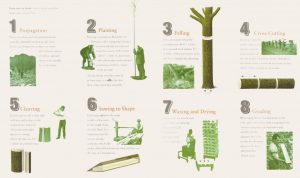

The following is a great illustration of what occurs before we receive it in the workshop.

Once the clefts are received, the first job is to cut the wax ends off. The clefts are far wider than a cricket bat, so we trim the edges to the correct width. Then the clefts are stacked 4 x 4 so the air can continue to keep the wood in good condition. Good air flow prevents mould that can leave a stain on a final product.

The stacks of willow are not seen in Australia at many workshops, nor the distinctive aroma of the willow experienced. Mainly due to the low numbers of workshops that have the skills to take a cleft from this raw form, to that where it is ready for crafting. It is difficult to commit to this part of the process which is why many craft from part-made bats.

Recent Comments